Playground safety starts with the right surface material, which cushions falls and reduces injury risks. This guide offers material comparisons, practical safety tips, and expert advice to help you create a safer play environment for children.

Why Playground Surfacing Matters

Playground surfacing is the unsung hero of any play area, quietly working to protect children, ensure accessibility, and stand the test of time. Let me walk you through why choosing the right surface material is one of the most critical decisions you’ll make for your playground.

Safety First

The surface beneath a playground is more than just a foundation—it’s a safety net. Falls are the leading cause of playground injuries, and the right surfacing can significantly reduce the risk of serious harm. Materials like poured-in-place rubber, engineered wood fiber, and rubber mulch are designed to absorb impact, acting like a soft cushion when children tumble.

To meet safety standards, ensure your surfacing complies with ASTM F1292, which tests for impact attenuation. For example, if your playground includes a 6-foot-high slide, the surface must provide adequate shock absorption for a fall from that height. Always check the critical fall height rating of your chosen material and match it to the tallest equipment in your play area.

Beyond compliance, think about the details. Loose-fill materials like wood chips or sand require regular raking to maintain proper depth, while unitary surfaces like rubber tiles offer consistent protection with less upkeep. Your surface should feel like a reliable guardian, always ready to soften the blow when play gets a little too adventurous.

Accessibility and Usability

Playgrounds should welcome every child, regardless of ability, and your surfacing plays a key role in creating an inclusive environment. ADA-compliant materials, such as poured-in-place rubber or rubber tiles, provide smooth, stable surfaces that accommodate wheelchairs, walkers, and strollers.

Engineered wood fiber can also meet ADA standards when installed and maintained correctly, but it requires more frequent attention to prevent uneven areas or compacted spots. Think of your surface as a bridge, connecting children of all abilities to the joy of play.

Consider usability for all weather conditions. A surface that becomes slippery when wet or too hot under the sun can limit playtime. For example, rubber surfacing tends to stay cooler than asphalt or concrete, making it a safer choice for sunny climates. Choose materials that invite children to play year-round, rain or shine.

Durability and Maintenance

Your playground surface should be as resilient as the kids who play on it. High-quality materials withstand heavy foot traffic, weather extremes, and the test of time. For instance, poured-in-place rubber offers excellent durability, resisting cracking and fading even under constant use and exposure to UV rays.

Maintenance is the key to longevity. Loose-fill materials like sand or wood chips need regular replenishment and leveling, while unitary surfaces require periodic cleaning and inspections for damage. Create a maintenance schedule that includes tasks like pressure washing rubber surfaces or raking loose-fill materials to ensure consistent performance.

Investing in durable materials upfront saves money in the long run by reducing repair and replacement costs. Think of your surface as a long-term partner, working tirelessly to keep your playground safe, accessible, and inviting for years to come.

By prioritizing safety, accessibility, and durability, you’ll create a playground surface that not only meets standards but exceeds expectations. Every choice you make here reflects your commitment to providing a space where children can play freely and safely, no matter their abilities or the season.

Comparing Playground Surface Materials

Choosing the right playground surface material is one of the most critical decisions you’ll make, as it directly impacts safety, accessibility, and long-term maintenance. Each material has its own strengths and challenges, and understanding these will help you make a decision that aligns with your goals and budget. Let’s explore the options, grouped into loose-fill and unitary materials, to help you find the best fit for your playground.

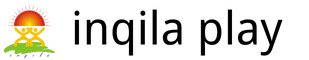

Loose-Fill Materials

Engineered Wood Fiber (EWF) is a popular choice for its affordability and natural appearance. It provides excellent shock absorption and meets ADA standards when properly installed and maintained. However, EWF requires regular raking to maintain even coverage and the recommended depth of 12 inches for most equipment. Over time, it decomposes and compacts, leading to ongoing replenishment costs. If you’re looking for a cost-effective option and are prepared for regular upkeep, EWF is a reliable choice.

Rubber Mulch offers an eco-friendly alternative, made from recycled tires. It’s durable, weather-resistant, and available in vibrant colors, making it visually appealing. However, it can scatter outside the play area and retains heat, which may be a concern in hot climates. While it requires less frequent replenishment than EWF, regular raking and containment are necessary to keep it in place. Rubber mulch is ideal for those prioritizing durability and sustainability, but it’s less suitable for areas with extreme heat.

Sand and Pea Gravel are budget-friendly options often found in older playgrounds. While they provide some impact absorption, they fall short in accessibility and cleanliness. Sand tends to track into shoes, and pea gravel scatters easily, creating a mess. Neither material meets ADA standards, making them less inclusive. These materials are best suited for low-budget projects or temporary installations but may not meet modern safety and accessibility expectations.

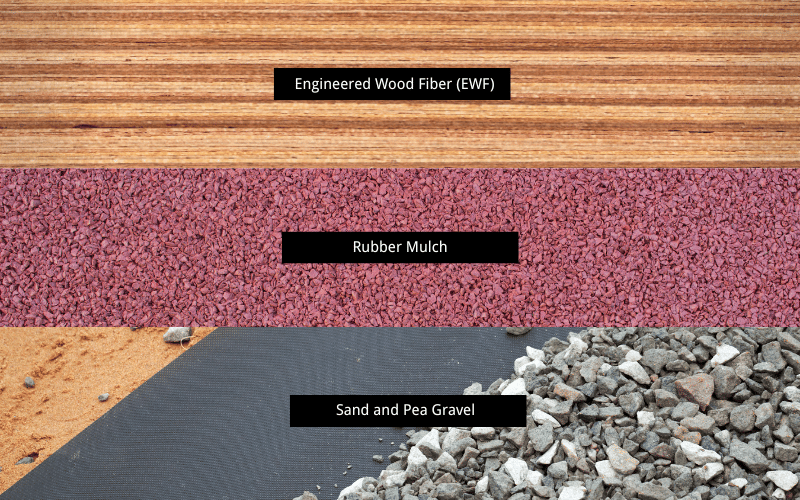

Unitary Materials

Poured-in-Place (PIP) Rubber is the gold standard for playground surfacing, offering a seamless, durable, and highly customizable solution. It provides consistent impact absorption, meets ADA standards, and can be tailored with colors and patterns to match your playground’s theme. While the upfront cost and professional installation requirements are high, its low maintenance and long lifespan make it a worthwhile investment for high-traffic or premium play areas.

Rubber Tiles provide a modular alternative to PIP rubber, combining durability with easy installation and repair. They are ADA-compliant and allow for individual tile replacement if damaged, making them a practical choice for long-term use. However, seams between tiles can shift or collect dirt over time, requiring occasional adjustments. Rubber tiles are an excellent option for those seeking a balance between durability and flexibility, especially in smaller play areas.

Artificial Turf with Infill offers the aesthetic appeal of natural grass with the added benefits of low maintenance and excellent drainage. It’s ADA-compliant and provides a soft, consistent surface, but it can become uncomfortably hot in direct sunlight. While the initial installation cost is high, its minimal upkeep makes it a practical choice for areas where a natural look is desired. Artificial turf works well in shaded or temperate climates where heat isn’t a significant concern.

Making the Right Choice

When selecting a playground surface, consider your priorities: safety, accessibility, durability, and budget. Loose-fill materials like EWF and rubber mulch are cost-effective but require regular maintenance, while unitary materials like PIP rubber and rubber tiles offer long-term durability and accessibility at a higher upfront cost. Artificial turf provides a natural aesthetic but may not suit all climates. By weighing these factors and aligning them with your specific needs, you can create a safe, inclusive, and enjoyable play environment that stands the test of time.

Key Factors to Consider When Choosing a Surface

Selecting the right playground surface is like building the foundation of a house—it’s the base that supports everything else. A well-chosen surface not only ensures safety but also enhances accessibility, durability, and visual appeal. Let’s break down the key factors you need to consider, so your playground can deliver on every front.

Safety and Compliance

Safety is the cornerstone of any playground surface. Start by understanding critical fall height ratings, which measure the maximum height from which a child can fall without risking serious injury. For example, if your tallest play structure is 8 feet, your surface must provide adequate impact attenuation for that height. Materials like poured-in-place rubber or engineered wood fiber (EWF) are designed to meet these requirements, but always verify the ratings with your supplier.

Compliance with ASTM (American Society for Testing and Materials) and CPSC (Consumer Product Safety Commission) standards is non-negotiable. These guidelines ensure your surface meets rigorous safety benchmarks, from impact absorption to material quality. Partner with reputable manufacturers who can provide certifications for their products. Think of these standards as the safety net that protects both children and your business from unnecessary risks.

Accessibility

Playgrounds should welcome every child, regardless of ability. To achieve this, your surface must comply with ADA (Americans with Disabilities Act) standards, which require smooth, stable, and slip-resistant materials. Options like poured-in-place rubber, rubber tiles, and properly installed EWF can accommodate wheelchairs, walkers, and strollers, ensuring inclusive play for all.

Design considerations also matter. For example, create pathways that connect play zones with accessible routes, and avoid loose-fill materials like sand or pea gravel in areas where mobility devices are common. Your surface should act as a bridge, not a barrier, allowing every child to explore and enjoy the playground freely.

Cost and Maintenance

Balancing upfront costs with long-term expenses is crucial. Initial installation costs vary widely—loose-fill materials like EWF or rubber mulch are more affordable to install but require frequent replenishment, while unitary surfaces like poured-in-place rubber or rubber tiles have higher upfront costs but lower maintenance needs.

Consider the maintenance schedule for your chosen material. Loose-fill surfaces need regular raking and topping off to maintain proper depth, while unitary surfaces require periodic cleaning and inspections for damage. For example, a poured-in-place rubber surface might need pressure washing every few months, while EWF requires weekly raking to prevent compaction. Choose a material that aligns with your budget and your team’s capacity for upkeep.

Durability and Environmental Impact

Your playground surface should be as resilient as the children who play on it. Weather resistance is key—materials like poured-in-place rubber and rubber tiles hold up well against UV exposure, rain, and temperature fluctuations, while loose-fill options may degrade or scatter over time.

If sustainability is a priority, look for surfaces made from recycled materials, such as rubber mulch or poured-in-place rubber made from recycled tires. These options not only reduce environmental impact but also demonstrate your commitment to eco-friendly practices. A durable, sustainable surface is like a loyal friend—reliable, long-lasting, and good for the planet.

Aesthetics and Design

A playground’s surface isn’t just functional—it’s also a canvas for creativity. Color options and themed designs can transform your space into a vibrant, engaging environment. For example, poured-in-place rubber can be customized with bright colors, patterns, or even logos, while rubber tiles offer modular designs that can match your playground’s theme.

Consider how the surface complements the overall aesthetic of your playground. A jungle-themed play area might benefit from green and brown tones, while a space-themed playground could feature bold blues and silvers. The right design enhances the visual appeal of your playground, making it a destination families will remember and revisit.

Bringing It All Together

When choosing a playground surface, think of it as the foundation of a child’s adventure. Prioritize safety and compliance to protect young explorers, ensure accessibility to welcome every child, and balance costs with long-term maintenance needs. Opt for durable, eco-friendly materials that can withstand the elements, and don’t forget to add a splash of creativity with colors and designs. By considering these factors, you’ll create a playground surface that’s not just functional but also inspiring—a place where children can play, grow, and thrive.

Avoiding Common Pitfalls

Choosing the wrong playground surface is like building a house on shaky ground—it compromises safety, usability, and long-term success. Over the years, I’ve seen how poor surfacing decisions can lead to avoidable problems that ripple through every aspect of a playground. Let me guide you through the risks and how to steer clear of them.

Risks of Poor Surfacing Choices

Increased Injuries and Long-Term Health Implications

The surface beneath a playground is the first line of defense against injuries, and cutting corners here can have serious consequences. For example, using inadequate materials like concrete or asphalt—or even improperly installed loose-fill options—can lead to more severe injuries from falls. A child falling from a 6-foot climbing structure onto a hard or poorly cushioned surface risks broken bones or head trauma, injuries that could have been mitigated with proper impact-absorbing materials.

Beyond immediate injuries, poor surfacing can also contribute to long-term health issues. Hard or uneven surfaces can strain children’s joints during play, especially in high-traffic areas like swings or slides. To avoid these risks, always choose materials with proven impact attenuation, such as poured-in-place rubber or engineered wood fiber, and ensure they are installed to meet critical fall height requirements. Think of your surface as a safety net—it should always be ready to catch a child when play takes an unexpected turn.

Compliance Failures and Potential Legal Liabilities

Failing to meet safety standards like ASTM F1292 or ADA accessibility guidelines can expose your playground to legal risks. Non-compliant surfaces not only jeopardize children’s safety but also open the door to lawsuits and fines. For instance, a playground with uneven or compacted loose-fill material may fail ADA requirements, making it inaccessible to children with mobility devices.

To avoid compliance pitfalls, work with reputable suppliers who provide certified materials and professional installation. Regularly inspect your surface to ensure it continues to meet safety and accessibility standards. Compliance isn’t just about avoiding penalties—it’s about building trust with your community and showing families that their children’s safety is your top priority.

Higher Maintenance Costs and Reduced Play Value

Choosing a surface based solely on upfront cost often leads to higher expenses down the road. For example, while sand or pea gravel may seem budget-friendly initially, they require constant replenishment and raking to maintain proper depth and coverage. Over time, these ongoing maintenance needs can outweigh the savings, leaving you with a surface that’s both costly and ineffective.

Poor-quality materials also degrade faster, reducing the play value of your playground. A surface that becomes uneven, compacted, or scattered diminishes the overall experience for children and parents alike. Imagine a child trying to navigate a play area with exposed hard spots or tripping hazards—it’s not just frustrating; it’s unsafe.

Investing in durable, low-maintenance materials like poured-in-place rubber or rubber tiles may require a higher initial investment. Still, they pay off in the long run with reduced upkeep and consistent performance. Think of it as planting a tree with deep roots—it may take more effort upfront, but it will stand firm for years to come.

How to Avoid These Pitfalls

To sidestep these common mistakes, start with a clear understanding of your playground’s needs. Assess the height of your equipment, the expected foot traffic, and the local climate to choose a surface that aligns with your goals. Partner with experienced professionals for installation and maintenance, and prioritize materials that balance safety, durability, and accessibility.

By making informed decisions and avoiding shortcuts, you’ll create a playground that not only meets but exceeds expectations—a space where children can play freely, parents can relax, and your community can thrive. Remember, the right surface isn’t just a foundation; it’s a promise of safety, fun, and lasting value.

Expert Tips for Choosing and Maintaining Playground Surfaces

Selecting and maintaining the right playground surface is like nurturing a garden—it requires careful planning, regular attention, and a commitment to growth. Over the years, I’ve seen how the right approach can transform a play area into a safe, vibrant space that families cherish. Here are my top tips to help you make the best decisions and keep your playground in peak condition.

Consulting Professionals

When it comes to playground surfaces, don’t go it alone. Certified playground safety experts are your best allies in navigating the complexities of safety standards, material options, and installation techniques. These professionals bring a wealth of knowledge, from understanding ASTM and CPSC guidelines to recommending materials that suit your specific needs.

For example, if your playground features tall climbing structures, a safety expert can calculate the critical fall height and recommend surfaces like poured-in-place rubber or engineered wood fiber to provide adequate impact attenuation. They can also guide you on ADA compliance, ensuring your playground is accessible to children of all abilities. Think of these experts as the architects of your playground’s foundation—they help you build it right from the start.

When hiring a professional, look for certifications like CPSI (Certified Playground Safety Inspector) and ask for references or examples of past projects. A good consultant doesn’t just provide advice; they partner with you to create a space that’s safe, inclusive, and tailored to your community’s needs.

Regular Inspections

A playground surface is only as good as its maintenance. Establishing a regular inspection schedule is essential to ensure safety and longevity. Start with daily visual checks for obvious hazards like debris, uneven areas, or damage. For example, loose-fill materials like wood chips or rubber mulch should be raked and leveled to maintain proper depth, while unitary surfaces like rubber tiles or poured-in-place rubber should be inspected for cracks or wear.

Schedule more thorough inspections monthly or quarterly, depending on usage. These should include measuring the depth of loose-fill materials, checking for drainage issues, and testing the stability of unitary surfaces. Keep a detailed log of your inspections and maintenance activities—this not only helps you stay organized but also provides documentation in case of an incident.

Don’t wait for problems to escalate. Address issues immediately, whether it’s replenishing compacted wood fiber, replacing a damaged rubber tile, or repairing a crack in a poured-in-place surface. A well-maintained surface is like a loyal guardian, always ready to protect children during play.

Balancing Safety and Fun

Safety is paramount, but it shouldn’t come at the expense of play value. A playground surface should enhance the experience, not limit it. For instance, while poured-in-place rubber offers excellent safety and accessibility, it can also be customized with vibrant colors, patterns, or even games like hopscotch or mazes. These design elements add an extra layer of fun while maintaining safety standards.

Consider the needs of different age groups when choosing your surface. Toddlers benefit from soft, sensory-rich materials like rubber tiles, while older children may prefer surfaces that support more dynamic play, such as climbing or running. By tailoring your surface to the activities it supports, you create a space that’s both safe and engaging.

Remember, a playground is more than just a collection of equipment—it’s a stage for imagination, exploration, and connection. Your surface should act as a silent partner, providing the safety and support children need to play freely and confidently.

Bringing It All Together

Choosing and maintaining a playground surface is an ongoing commitment, but the rewards are immeasurable. By consulting professionals, establishing a robust maintenance schedule, and balancing safety with play value, you’ll create a space that families trust and love. Your playground surface isn’t just a foundation—it’s a promise to your community, ensuring every child can play, grow, and thrive in a safe and joyful environment.

FAQs

Q: What is the safest outdoor playground surface material?

A: Poured-in-place (PIP) rubber is one of the safest outdoor playground surface materials due to its seamless design, excellent impact absorption, and ADA compliance. Engineered wood fiber (EWF) and rubber mulch are also safe options when installed and maintained correctly. Always choose materials that meet ASTM F1292 standards for impact attenuation to ensure they provide adequate protection for falls.

Q: How often should playground surfaces be inspected?

A: Inspect playground surfaces daily for visible hazards like debris, uneven areas, or damage. Perform more thorough inspections monthly or quarterly, depending on usage, to check for issues like compacted loose-fill materials, drainage problems, or wear and tear on unitary surfaces. Regular inspections help maintain safety and extend the lifespan of your surface.

Q: Can existing playground surfaces be upgraded?

A: Yes, you can upgrade existing playground surfaces to improve safety, accessibility, or aesthetics. For example, you can replace loose-fill materials like sand or pea gravel with ADA-compliant options like poured-in-place rubber or rubber tiles. Consult a certified playground safety expert to assess your current surface and recommend the best upgrade options.

Q: What certifications should I look for in surfacing materials?

A: Look for materials that meet ASTM F1292 standards for impact attenuation and ASTM F1951 standards for ADA accessibility. Additionally, check for certifications from reputable organizations like the International Play Equipment Manufacturers Association (IPEMA), which ensures the materials meet industry safety and quality standards.

Q: How does weather affect playground surfacing?

A: Weather can impact playground surfacing in several ways. Extreme heat can make rubber surfaces hot to the touch, while heavy rain can cause drainage issues in loose-fill materials like wood chips. Freezing temperatures may lead to cracking in some unitary surfaces. Choose weather-resistant materials and ensure proper installation to minimize these effects. Regular maintenance, like clearing debris and addressing drainage problems, helps surfaces withstand weather challenges.

Conclusion

Choosing the right playground surface is essential for ensuring safety, accessibility, and durability. Evaluate your specific needs, such as equipment height, usage, and climate, to make an informed decision. Consult certified experts to receive tailored solutions that align with your goals and create a play space where children can thrive.